- Home Page

- Company Profile

-

Our Products

- Strips & Coils

- Lightning Arrester

- Chemical Earthing Electrodes

- Earthing Material

- Chemical Bag Fill Compound

- Copper Plates

- HDPE Pit Cover

- Earthing Pit Cover

- GI BUS BAR

- Aluminium Strips

- Earthing Clamps

- Electricals Rubber Mats

- Funnel With Mesh

- Cable Trays

- Manhole Covers

- Earthing Strips

- Lightning Arrester Manufacturer India

- Pit Cover

- Earthing Electrodes Supplier India

- Rubber Mats

- Copper Ground And Earthing Rods

- Earthing Plates

- Earthing Pipes

- Ashlok Chemical Earthing Supplier

- Earthing Busbar

- Chemical Earthing Electrode Supplier India

- Earthing Wires

- Junction Boxes

- Backfill Compound

- Earthing Funnels

- DMC Electrical Insulators

- Earthing Coils

- Ladder Cable Tray

- Nylon Cable Ties

- Flexible Conduit Pipe

- Lightning Arrester Mast

- Earthing Installation Service

- Copper Flexible Connectors

- Equipotential Bonding Bars

- Earthing Strip

- Bimetallic Strips

- Earthing Electrode

- Contact Us

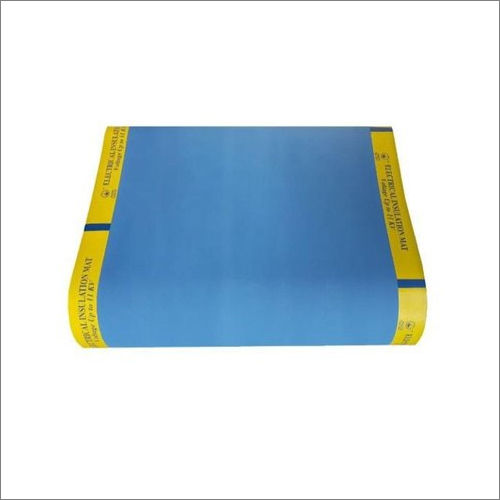

Electrical Insulating Rubber Mats

450 INR/Piece

Product Details:

- Size 1 x 2 m

- Thickness 2.0 mm to 3.0 mm (standard), customized options available

- Place of Origin India

- Material Rubber

- Back Material Rubber

- Style Plain, Ribbed

- Design Anti-skid/top ribbed surface

- Click to View more

X

Electrical Insulating Rubber Mats Price And Quantity

- 450 INR/Piece

- 10 Piece

- >250%

- Up to 65 kV depending on thickness

- >15 MPa

- Up to 33 kV (varies as per mat thickness)

- -25°C to +55°C

- Both sides textured or one side ribbed, one side plain

- <1%

Electrical Insulating Rubber Mats Product Specifications

- Plain, Ribbed

- 2.0 mm to 3.0 mm (standard), customized options available

- Rubber

- Solid/Plain

- Moulded/Vulcanized

- Oil resistant, Flame retardant, Durable, Anti-slip

- India

- Wipe clean or water wash

- Electrical insulation for personnel protection in high voltage areas

- Blue

- Rubber

- Anti-skid/top ribbed surface

- 1 x 2 m

- Rectangular

- >250%

- Up to 65 kV depending on thickness

- >15 MPa

- Up to 33 kV (varies as per mat thickness)

- -25°C to +55°C

- Both sides textured or one side ribbed, one side plain

- <1%

Product Description

Product details

| Pattern | Plain |

| Country of Origin | Made in India |

| Thickness | 2 m |

| Material | Rubber |

| Color | Blue |

| Usage/Application | Electrical Insulation |

| Size | 1 x 2 m |

- Size: 8 x 10 m

- Thickness: 2 to 3 mm

Safety and Performance First

These electrical insulating rubber mats are crafted for optimal safety during operations near high-voltage equipment. With a dielectric strength reaching up to 65 kV and a working voltage up to 33 kV, these mats act as a reliable barrier against dangerous electrical shocks. Their robust construction and durable material ensure a long service life and consistent performance even under challenging conditions.

Versatile Design & Easy Maintenance

Offered in sizes of 1 x 2 meters and a thickness range of 2.0 mm to 3.0 mm, these mats can also be customized for unique facility needs. Available in both plain and ribbed styles, their anti-skid textured or ribbed surfaces enhance safety further. Maintenance is simple, requiring only a wipe down or water wash, making them highly practical for regular use in demanding environments.

FAQs of Electrical Insulating Rubber Mats:

Q: How do electrical insulating rubber mats provide safety in high-voltage areas?

A: These mats are engineered with high dielectric strength (up to 65 kV) and serve as an effective insulation barrier underfoot, preventing electrical shocks while working near live electrical equipment. Their anti-slip surfaces and durable build enhance workplace safety for employees.Q: What is the maximum voltage these rubber mats can withstand?

A: The mats offer a working voltage capacity of up to 33 kV, depending on their thickness. For dielectric strength, they are tested up to 65 kV, making them suitable for use in various high-voltage installations.Q: When should these insulating mats be replaced or inspected?

A: It is recommended to inspect the mats regularly for signs of wear, cuts, or chemical damage. Mats should be replaced if their surface integrity is compromised or if they fail electrical insulation tests as per safety regulations.Q: Where are these insulating mats typically used?

A: These mats are commonly installed in front of electrical panels, control rooms, substations, transformer rooms, and other high-voltage areas in power plants, factories, and industrial sites where personnel require protection from electric shock.Q: What is the process for cleaning and maintaining these mats?

A: Cleaning is straightforward: simply wipe the surface clean with a damp cloth or use water washing methods. Their oil and flame resistance ensures that regular maintenance does not degrade their protective qualities.Q: How does the mats design contribute to its performance?

A: Featuring options for textured, ribbed, or plain surfaces, the mats provide superior grip to prevent slips. Their vulcanized/molded construction ensures high breaking elongation (>250%) and tensile strength (>15 MPa), contributing to long-term durability and consistent insulation.Q: What are the key benefits of using these mats in electrical setups?

A: These mats significantly reduce the risk of electrical shock, offer excellent resistance to oil and flames, and perform reliably across a wide temperature range. Their low water absorption and anti-skid properties further ensure workplace safety and comfort for personnel.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email