- Home Page

- Company Profile

-

Our Products

- Strips & Coils

- Lightning Arrester

- Chemical Earthing Electrodes

- Earthing Material

- Chemical Bag Fill Compound

- Copper Plates

- HDPE Pit Cover

- Earthing Pit Cover

- GI BUS BAR

- Aluminium Strips

- Earthing Clamps

- Electricals Rubber Mats

- Funnel With Mesh

- Cable Trays

- Manhole Covers

- Earthing Strips

- Lightning Arrester Manufacturer India

- Pit Cover

- Earthing Electrodes Supplier India

- Rubber Mats

- Copper Ground And Earthing Rods

- Earthing Plates

- Earthing Pipes

- Ashlok Chemical Earthing Supplier

- Earthing Busbar

- Chemical Earthing Electrode Supplier India

- Earthing Wires

- Junction Boxes

- Backfill Compound

- Earthing Funnels

- DMC Electrical Insulators

- Earthing Coils

- Ladder Cable Tray

- Nylon Cable Ties

- Flexible Conduit Pipe

- Lightning Arrester Mast

- Earthing Installation Service

- Copper Flexible Connectors

- Equipotential Bonding Bars

- Earthing Strip

- Bimetallic Strips

- Earthing Electrode

- Contact Us

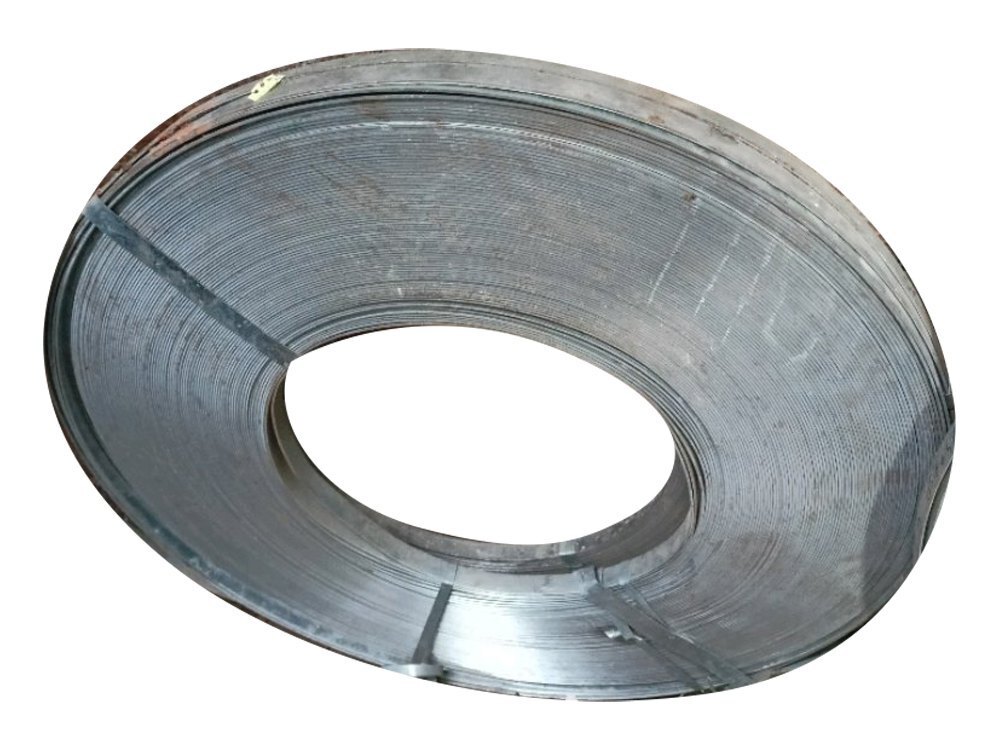

GI Strips Coils

70 INR/Meter

Product Details:

- Technique Cold Rolled

- Coil Thickness 0.18-2 mm Millimeter (mm)

- Application Therefore, this range is highly demanded in aerospace, nuclear, medical and other industries.

- Click to View more

X

GI Strips Coils Price And Quantity

- 70 INR/Meter

- 10 , , Meter

GI Strips Coils Product Specifications

- Therefore, this range is highly demanded in aerospace, nuclear, medical and other industries.

- 0.18-2 mm Millimeter (mm)

- Cold Rolled

GI Strips Coils Trade Information

- Delhi

- Cash in Advance (CID)

- 5000 , , Meter Per Month

- 2-7 Days

- Yes

- Contact us for information regarding our sample policy

- Asia

- North India

Product Description

We have successfully established in the market as a foremost manufacturer and supplier of GI Strips Coils. Generally, the offered range is designed while selecting galvanized iron, which is used for providing high ductility and strong structure. Therefore, this range is highly demanded in aerospace, nuclear, medical and other industries. At our well developed production unit, the entire production is completed with the aid of modern day machine in compliance with set quality standards. We are offering GI Strips Coils to our clients in different specifications at cost effective rates.Features: Overload protection Good ductility Rust proof Specifications: Width: 40-1250mm or as your requirement Thickness: 0.18-2mm Width Tolerance: /_0.02mm Frequently Asked questions 1. What makes strips and coils different from one another? Ans - Between coils and strips, there is only a difference in breadth. Strip is the term used when a coil is divided up into several smaller, narrower coils. 2. How do GI coils work? Ans - ALUMINUM STEEL (GI) a hot dip Cold rolled steel coil is processed through a molten zinc bath at temperatures of about 460 degrees Celsius to create galvanised steel coil. The steel coil substrates zinc coating serves as a barrier between the atmosphere and the metals surface. 3. What is the GI earthing strip standard? Ans - The minimum and maximum length requirements for galvanised iron earthing strips are 7 and 10 metres, respectively. 4. Why do people earth with GI strips? Ans - G.I. earthing uses mild steel pipes with a galvanised iron coating to finish the earthing system. Considering how well steel conducts electricity, any potentially harmful voltage can be sent to the ground and away from you.FAQs of GI Strips Coils:

Q: What manufacturing technique is used for GI Strips Coils?

A: GI Strips Coils are produced using the Cold Rolled technique.Q: What industries commonly use GI Strips Coils?

A: GI Strips Coils are highly demanded in aerospace, nuclear, medical, and other industries.Q: What is the coil thickness range of GI Strips Coils?

A: The coil thickness of GI Strips Coils ranges from 0.18 to 2 millimeters (mm).Q: Are GI Strips Coils suitable for applications requiring precision?

A: Yes, GI Strips Coils, produced through Cold Rolled techniques, are suitable for applications requiring high precision.Q: Can GI Strips Coils withstand demanding environments like those in aerospace or nuclear industries?

A: Yes, GI Strips Coils are designed to meet the demands of challenging environments in industries such as aerospace and nuclear.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email